Lifetime Warranty!

Ask Today about

Lifetime Warranty Control Panels

Combustion Instruments

A Flame Scanner is an instrument that has sensors that detects the presence of a flame while measuring its basic parameters. Such as (temperature, flicker frequency, DC Intensity, AC amplitude, ect…) It releases and output signal that is usable for safety shutdown operations and Interfaced control systems.

FLAME “ON”

FLAME “OFF”

Flame Scanners can be a cost saving feature by providing reliable flame information in multi-fuel & waste gas combustion plants. It can increase the boiler shutdown or start up time by monitoring the fuel usage required.

Flame Scanners are used in many applications. Listed here are a few of those applications:

- Power Generation

- Oil & Gas (refineries)

- Chemicals & Petrochemicals

- Pulp & Paper

- Minerals (Cement)

- Metals (Steel)

- Waste Incinerators

- Flare Stacks

“VFD”

Variable Frequency Drives

VFD is electronic device that controls the speed of motors or pumps. By controlling the speed and how a motor performs gives the motor longer life and it also being more efficient.

Drives can be industry specific. For example: The location of where a drive will be located, the size of drive there also may be other factors. Looking at all the specifics of a drive are very important when getting one to fit your application.

Invertek Drives have drives that fit many different applications. Listed below:

- Pump Control

- HVAC Building

- Elevators

- General Automation

- Marine Equipment

- Combustion Air Fans

VFD’s have a big energy savings when used right. Invertek Drives can be integrated into your PLC systems.

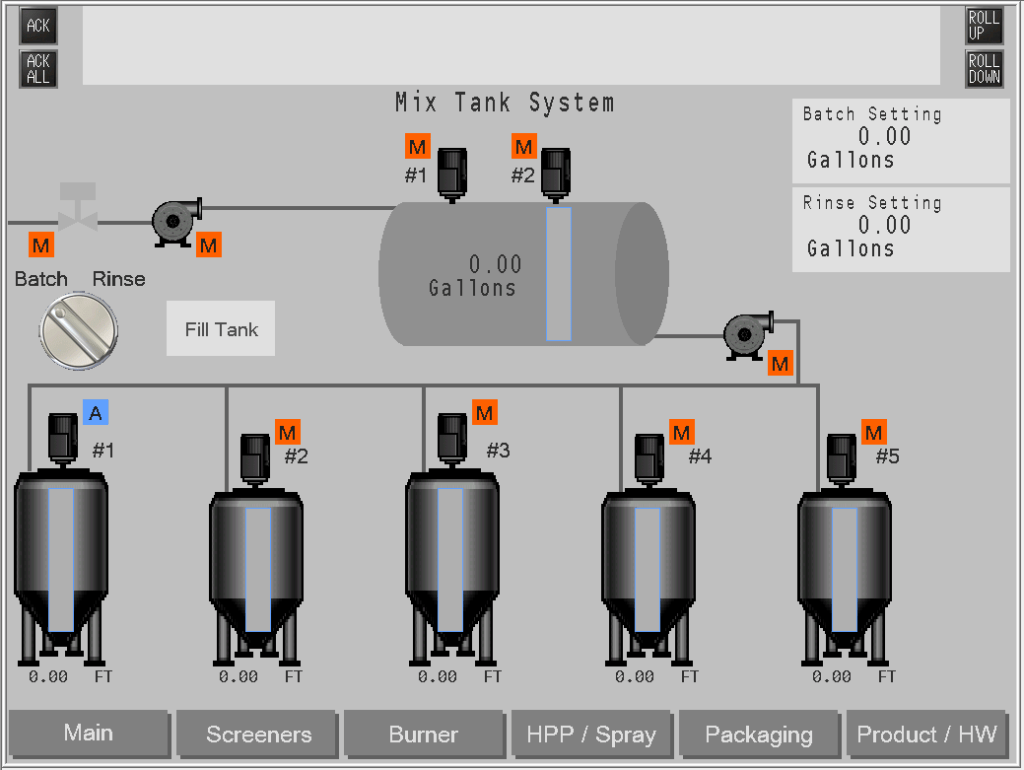

System Integration

System Integration is a specialized service that typically involves control panels, SCADA systems, PLC’s, VFD’s, HMI’s or any other components that communicate with each other in an automated system. Montana Controls supports new or existing systems and can work with plant personnel to recommend repairs or upgrade to keep your system online and reduce downtime. Montana Controls supports Allen-Bradley, Siemens, ABB, Schneider and other common manufacturers.

UL 508A Control Panel

What is a UL 508A? It is a verification that is required for many different applications that electrical inspectors looks for. Montana Controls LLC is a certified UL 508A panel shop. We can build control panels for any application. If you would like to learn more information about this or would like to see what applications we have built panels for click here.

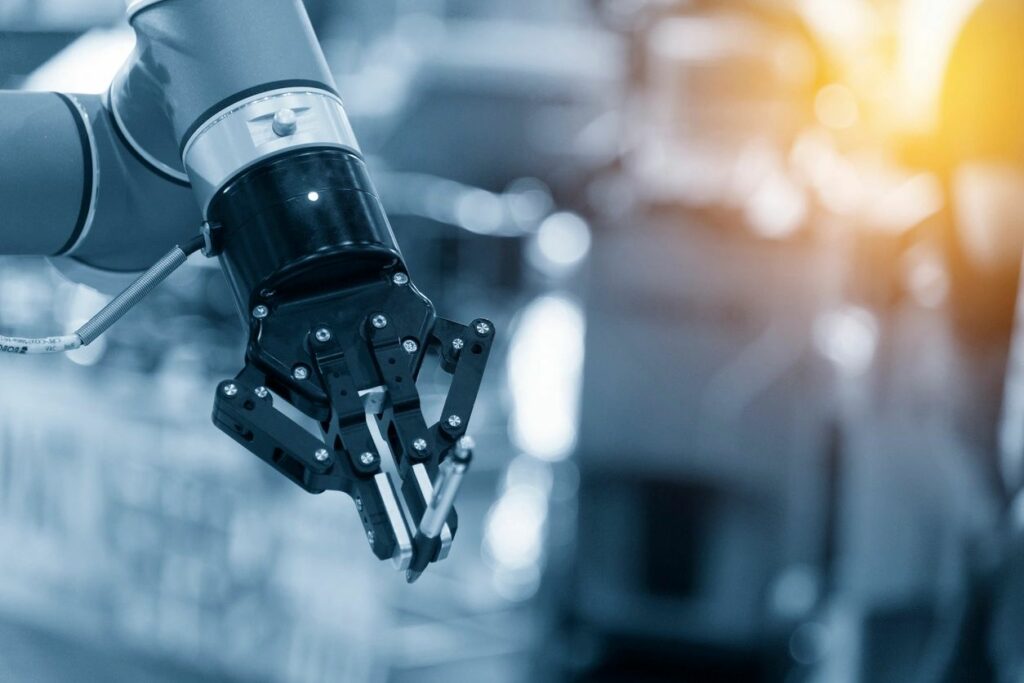

Robotics

Industrial Robotics is a industry that is growing every day. People don’t have to worry the robots are taking over the world, they are only helping do jobs that are more efficient to business and in some cases take the harmful to someone out of the equation. Industrial Robotics can help with welding, on assembly lines, manufacturing packaging and many more. If you are interested in learning more about the industrial robotics please inquire.

Why Automate?

First ask yourself, what does and automation service do?

In many cases, automation is the use of machinery such as computer processors, robots, sensors, automatic valves, pressure instruments and more to minimize the need for human interaction in a manufacturing process. Many may argue that automation is an alternative to the use of humans to get something done. Inevitably, this would reduce the availability of jobs in a particular market where full automation is becoming more economical for the business owner(s). This may be true in some instances, but often the choice to automate a process allows for job advancement opportunities and training for the operation and maintenance of automated systems. Just as common as automation being implemented to replace people, automation is used to help technicians perform a task that they otherwise would be unable to complete due to limitations such as speed, precision, or safety hazards. Our automation services install systems that are capable of making thousands of calculations in small periods of time. This allows efficient adjustment to different environments and variables that may take a typical technician or operator hours to perform. These delays and potential mistakes sometimes result in faulted processes and loss of revenue.

Knowledge With These Common Manufactures:

- Allen Bradley (Rockwell)

- Siemens

- ABB

- Hach

- Universal Robots

- Schneider Electric

- Many More…

Provider of Products:

- Invertek Drives

- Rocker

- Emerson

- Phoenix Contact

- ABB Flame Scanners

Authorized

UL 508A Industrial Control Panel Manufacturer:

- Design

- Engineering

- Fabrication

- Assembly

- Programming

- Installation

- Testing